Quality is a top priority for us: Only aluminum products that meet our strict customer specifications leave our plant.

We are continually optimizing our quality management system. In doing so, we check the quality of the entire system, the processes and the quality of all our products. We do this with the aim of constantly maintaining a high level of performance – and improving it if necessary.

Our quality management system meets the requirements of the aviation industry. This means that we have defined for ourselves a particularly high standard that applies to all our products. Since 2007, we have officially met all the requirements of EN 9100. Of course, we have been complying with the requirements of DIN ISO 9001 for many years now. Our Quality Management System is certified annually.

Do you require special testing done?

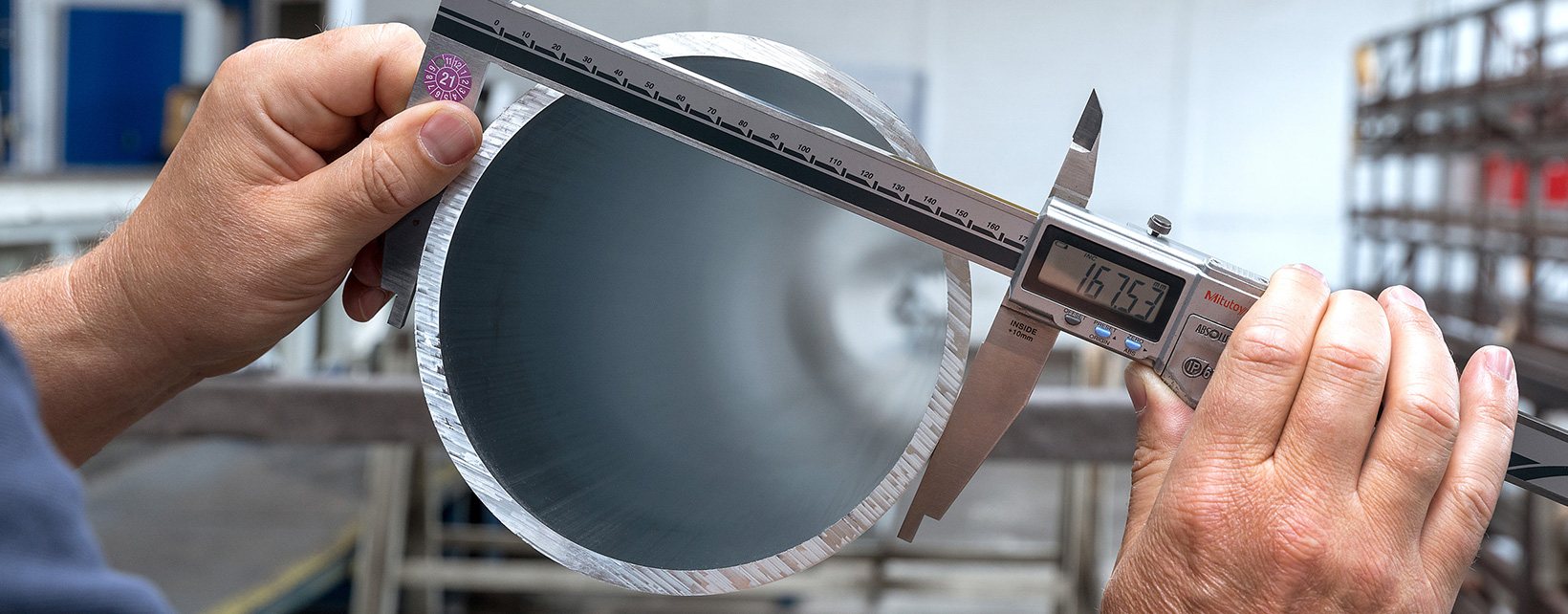

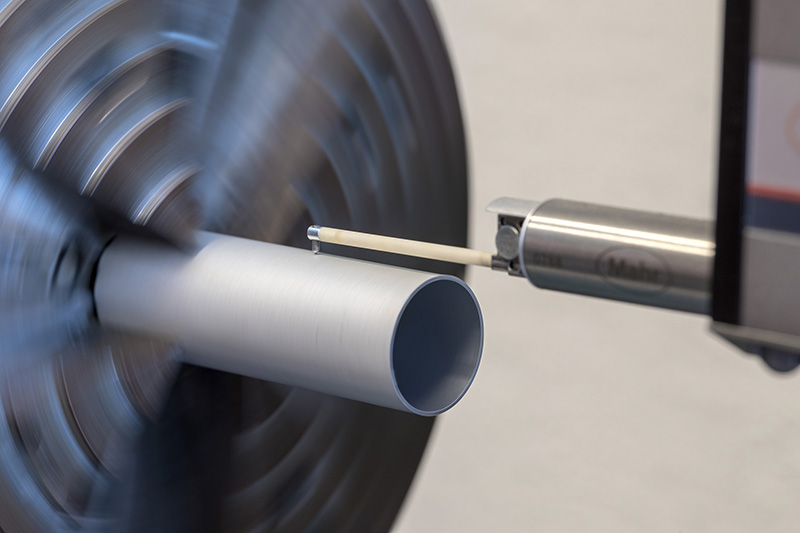

At our aluminum plant, we have all the necessary test procedures for the final acceptance of our products at your disposal. In addition to tensile and hardness tests, we can also perform non-destructive examinations – for example, with eddy current and ultrasonic systems, depending on the specification or customer requirements. Microscopic examinations for analyzing microstructures are carried out in our laboratory. Through our quality control tests we make sure that our products meet all the necessary requirements.

Do you require additional testing for your goods?

Additional testing procedures can be arranged on request. We can also arrange for an independent classification body if this is required for the acceptance of the production lot. We are pleased to be able to offer this service if so required.